” Style necessitates tricky numbers, so There exists temptation for the design staff to implement this assertion as being a remaining Excellent placement—that 20 air improvements is acceptable in a very Quality C space.”

These environments frequently deal with delicate Organic elements, and any contamination could compromise the safety and efficacy in the product.

In summary, Airlock systems would be the integral aspect and used in the varied manufacturing procedures to deliver a powerful barrier to forestall the contaminants and cross-contamination.

Bubble airlocks are specially appropriate for environments where by contamination Manage and containment are significant, including sterile manufacturing, cleanrooms, and biotechnology labs.

OSD producing airlocks are especially suitable for the manufacture of oral reliable dosage varieties e.g. tablets and capsules.

These airlocks consist of two doors that can not be opened at the same time, avoiding cross-contamination in between the two regions.

Personnel movement are going to be equally as complex since the motion of resources as it varies from form of operation and product or service that's made in the ability for example Vaccines & Strong compounds.

Air showers use significant-velocity air jets to blow away dust or other contaminants, ensuring that only cleanse materials are introduced into the cleanroom.

from just one facet deposits into the here airlock whatever they want to transfer and closes the door. Followed by another staff from the other side who open up the door and usually takes it. Here is the way the transference is completed, lacking direct interaction in between the environments on both of those ends.

Airlocks Enjoy an important part in ensuring the integrity of managed environments by making a barrier among different zones with various cleanliness concentrations. On this page, We are going to check out the different types of airlocks normally Employed in the pharmaceutical market as well as their significance in maintaining aseptic situations.

If your filters will not be functioning effectively, the airlock’s power to control contamination is compromised, leading to opportunity breaches in GMP compliance.

In bubble airlock force In the airlock is higher or positive As well as in adjacent sides, the pressure is a lot less or unfavorable.

Cross-contamination will also be prevented by creating a cascade airlock. For cascade airlock inside of granulation spot is managed unfavorable for example at 10 Pa and airlock is airlocks types preserved at much more positive e.

Materials Handling: MALs, However, are designed for materials decontamination. Their systems are optimized to get rid of particles from transferred products, typically using HEPA filters and air showers to clean surfaces ahead of moving into the cleanroom.

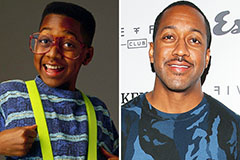

Jaleel White Then & Now!

Jaleel White Then & Now! Mr. T Then & Now!

Mr. T Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now!